Don't break the bank, break the valve!

Manufacturer BALL VALVES SINCE 2010

Don’t let expensive valves drain your budget – choose Welflow Valve and save!

03.

Thread: FF, MF, MM, BSPT/BSP/NPT

Butt-Welded(BW), Socket Welded(SW), Trip-Clamp

Flange Ends

OURMAINPRODUCTS

Keep your production plant running smoothly with Welflow Valve’s high-performance products.

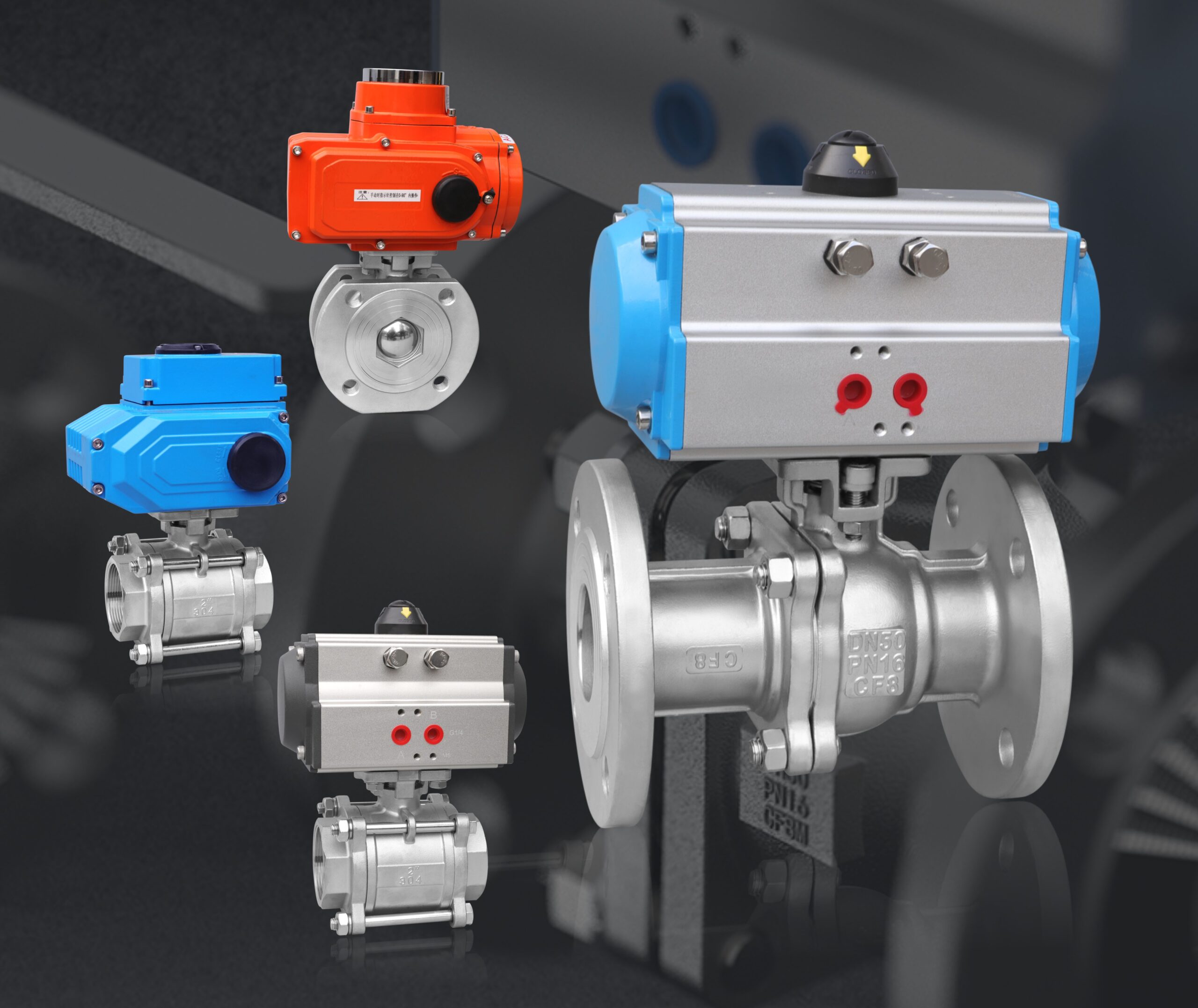

Pneumatic BALL valves

These types of ball valves could be installed actuator directly without Brackets.

THREAD BALL VALVE

It gets its name from the threaded connections used to connect the valve to the pipes.

Globe/Gate/Check Valve

A gate valve is a type of valve that controls the flow of fluid by lifting a gate (a flat or wedge-shaped disk) out of the fluid path.

Flange Gate Valve

This valve uses a gate to allow or stop the flow. The connection is flange ends. It’s commonly used in industries like oil and gas.

FLANGE GLOBE VALVE

This valve features a movable disc-type element and a stationary ring seat for controlling flow.

FLANGE CHECK VALVE

It, also known as a non-return valve, is a type of valve that allows fluid to flow in one direction only. The primary purpose of the check valve is to prevent backflow in the system.

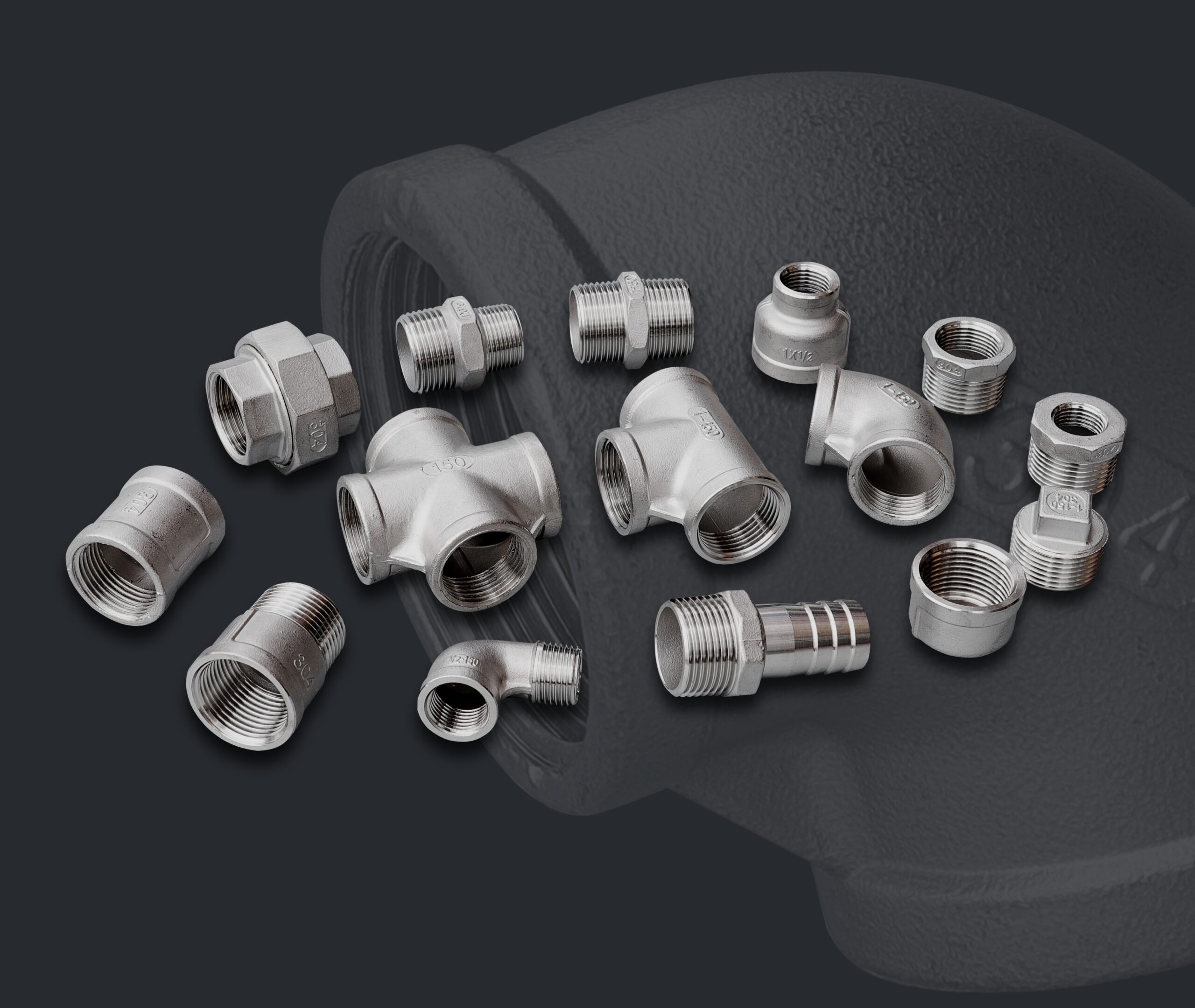

THREAD FITTINGS

It has internal or external threads that can be screwed onto the matching threads of another pipe or fitting. This makes them easy to install and remove without needing special equipment.

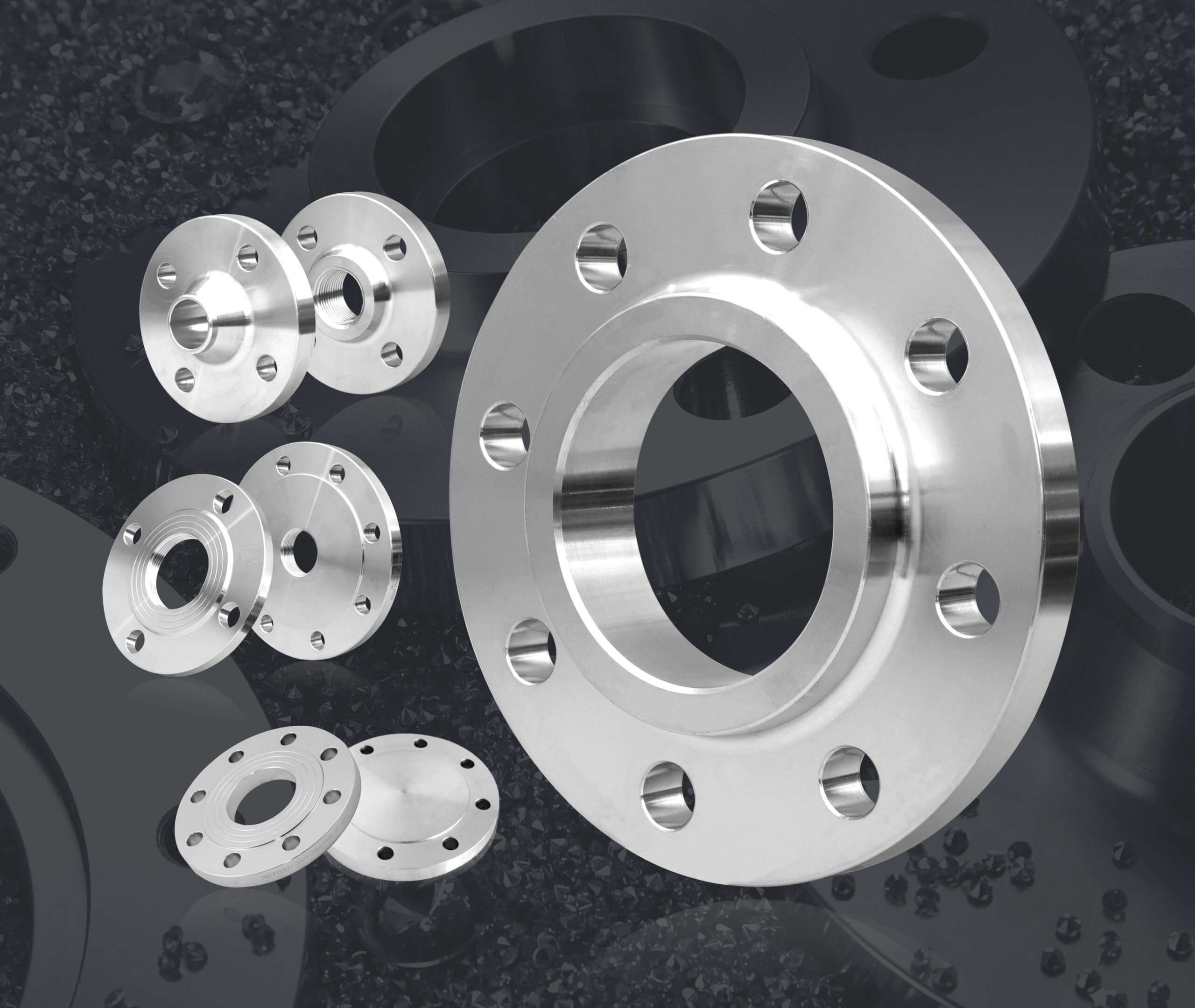

Forged flanges

Flanges come in many types, including slip-on flanges, weld neck flanges, blind flanges, threaded flanges, etc. Each type serves different purposes and is suitable for various applications.

Application Areas

Valves and Fittings are used in a wide range of applications across many different industries. Some common fields of application include:

WHAT SHOULD WE DO BEFORE INSTALLING VALVE & FITTINGS?

Valves and fittings are crucial for fluid systems, and correct installation is essential for safety and optimal performance.

- Choose the right valve and fitting for the job.

- Check them for defects before installing.

- Prepare the pipeline by cleaning it and removing sharp edges.

- Follow the manufacturer's instructions carefully.

- Make sure the valves and fittings are properly supported.

- Test them after installation to ensure they work correctly and don't leak.

why choose us for projects!

Reliable Quality, Long-Term Partnership: Choose Welflow Valve for Your Stainless Steel Needs

OEM/ODM SUPPORT

Processing to customer's drawing/sample Or drawing design according to the needs of working conditions.

QUALITY CONTROL

Our product control starts from wax investment casting; We Provide Testing Reports and accepts 3rd-party QC.

AFTER SALE SERVICE

Professional after-sales team, if it is a quality problem to implement the package return service.

Customized Packing

Accept custom-sized boxes, personalized color labels, and branded packaging materials as required.

PROFESSIONALSHIPPING PACKAGING

We understand that packaging and logistics can concern customers purchasing valves and fittings.

That’s why we offer professional packaging and logistics services, using high-quality materials and experienced personnel to ensure your valve and fittings arrive safely and securely.

Let us take care of the details so you can focus on your business.

Appreciated by our customers!

Don’t just take our word for it – read what our satisfied customers have to say.

Join our community of satisfied customers and experience the high-quality products and excellent customer service that Welflow Valve is known for.

FAQ OF WELFLOW

Which materials do we use in the production of Welflow products?

We use only high-quality stainless steel to ensure the durability and longevity of our products.

How does we ensure product quality?

We have strict quality control measures in place, including comprehensive testing and inspection at every stage of production.

What products do we offer, and how are they different from competitors?

We offer high-quality stainless steel ball valves, check valves, thread fittings, and flanges at a competitive price.

What is the lead time for Welflow Valve's products?

It varies, but we always aim for timely delivery.

How do We stay up-to-date with industry trends and technology?

Our team of experienced engineers and industry experts stay informed on the latest trends and technology developments to ensure that our products are always cutting-edge.

GET IN TOUCH WITH US

Get Free Samples of valves and pipe fittings for quality testing from welflow.